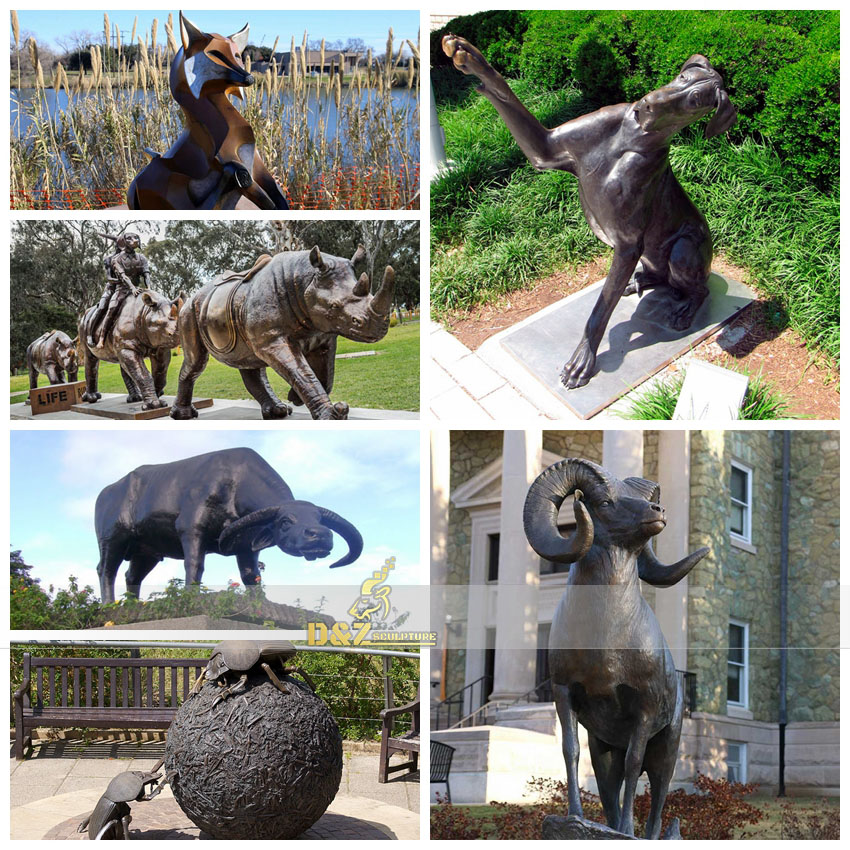

How casts which used “lost wax” an life size COPPER animal sculpture ?

Casting Bronze Animal Statue is a challenging too, as a professional company. But, we finished perfect more than 6000 pieces in 20 YEARS. We are always learning and exploring the perfection of casting process. Because, we know It allows our showcase we creativity animals art on the planet. The “lost wax” casting method I’ll be discussing.

I will use wild boar statue as examply .There is 9 steps of casting bronze animal statue…

-

-1 Model of animal creating .

Model of animal WILF Boar

Silicone mold and plaster mold

Artist creates 1:1 animal models of clay or other materials. Oil-based clays are commonly used. Because, they are softer AND Easy to modify. For the less detailed ANIMAL ones in continuous development of modern. Foam models can be made by 3D printing. We will say the clay (or the foam mold) as ‘base mold‘ in the later section.

-

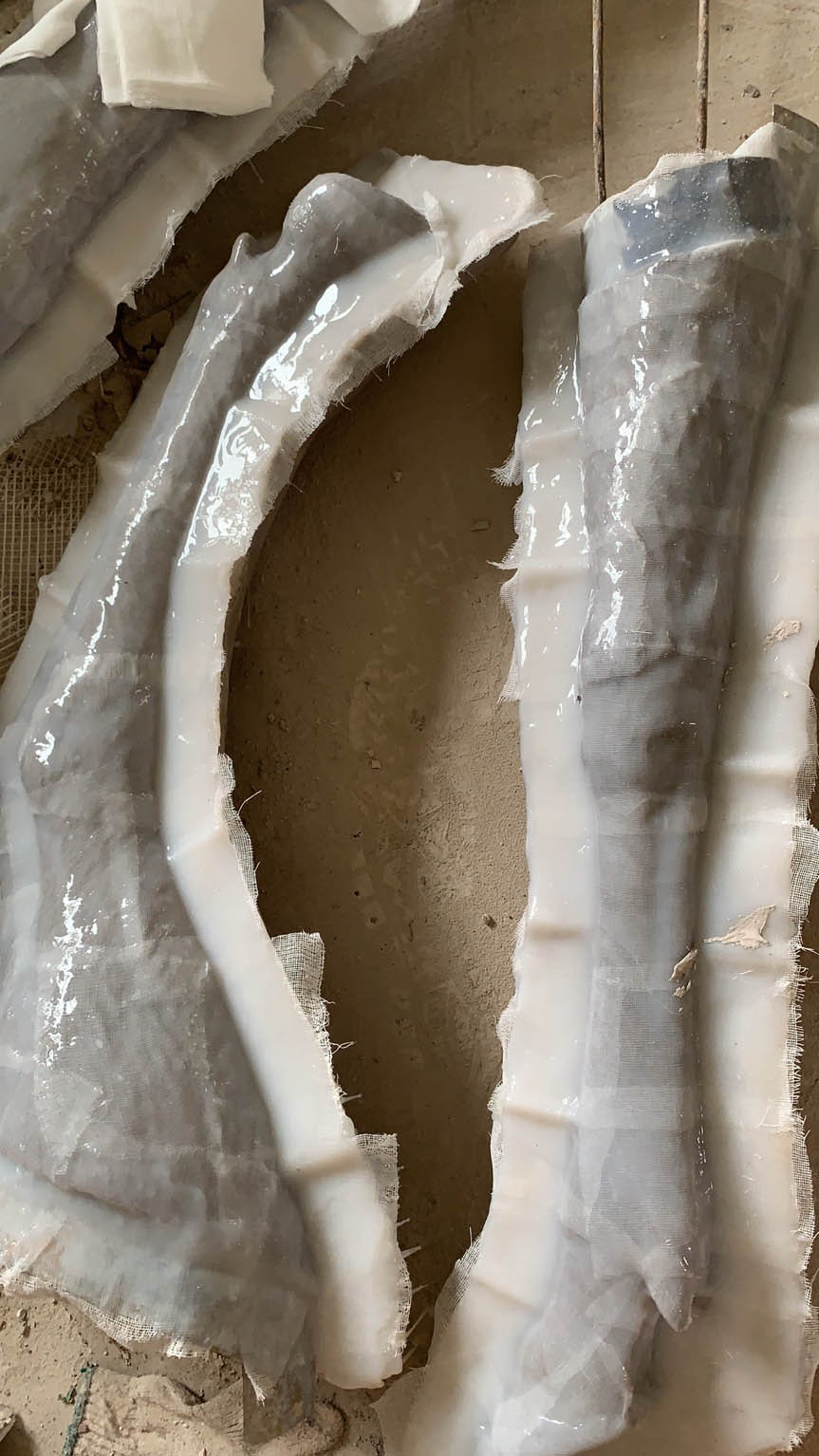

-2 Make new mold that can be cast.

We will say ‘new mold‘. Most animals the new molds are made of at least two pieces. There is a strong outer side and a softer inner side. The inner mold is the exact detail of the original ‘base model’. The inner side is usually made of latex, polyurethane rubber, or silicone. As a result, the external mold needs to play a supporting role. So, the outer side can be made from plaster.

However, it can also be made of fiberglass or other materials. During make new mold. Place some gaskets in above the ‘base mold’. In order to make the new mold in the process. Replication of the ‘base mold’ is thorough and accurate. If have long, thin part extending out. We tend to cut from the original ‘base mold’. And, separate make mold from new mold. Of course, sometimes many base moulds are needed or many separate base mold. Construct to complete the reproduction of the model. Especially in large animal models.

-

-3 Cast wax mold.

When the castable copper mold is complete. Start making wax molds.

Firstly, pour the melted wax into new mold. Furthermore, shaking causes the inner surface to form a uniform coating, usually about 1/8 inch (3mm) thick. (Another method of casting wax molds is. Fill the mold with molten wax. Also, let the wax cool off. Until the desired thickness is set on the surface of the mold and stops. ). Pour out the rest of the wax again from new mold. Turn the mould upside down to allow the wax layer to cool and harden.

Secondly, remove the wax mold from new mold. Remove the wax mould from the new mould. Of course, this step can be repeated many times. Multiple versions of the wax mold can be made. The durability of the new mold is required for making multiple copies of the new mold.

Thirdly, repair wax molds. On each hollow wax mold. It must be repaired before it can be used. Here’s my main point. With heated metal tools.” By melting the excess wax. And, supplement the defective loopholes.”. This method of repairing wax molds. If there are many separate parts of the wax mold. In this step. We need to go through this step. Combine separate parts of the wax mold together. Because, the wax mold surface must not have any any defect. Close to the animal sculpture. ( Take advantage of the plasticity of wax . And, easy to repair and so on. The wax mold can be repaired more finely. For example, the hair of lions, tigers and other animals can be reflected. ). The wax mold finished.